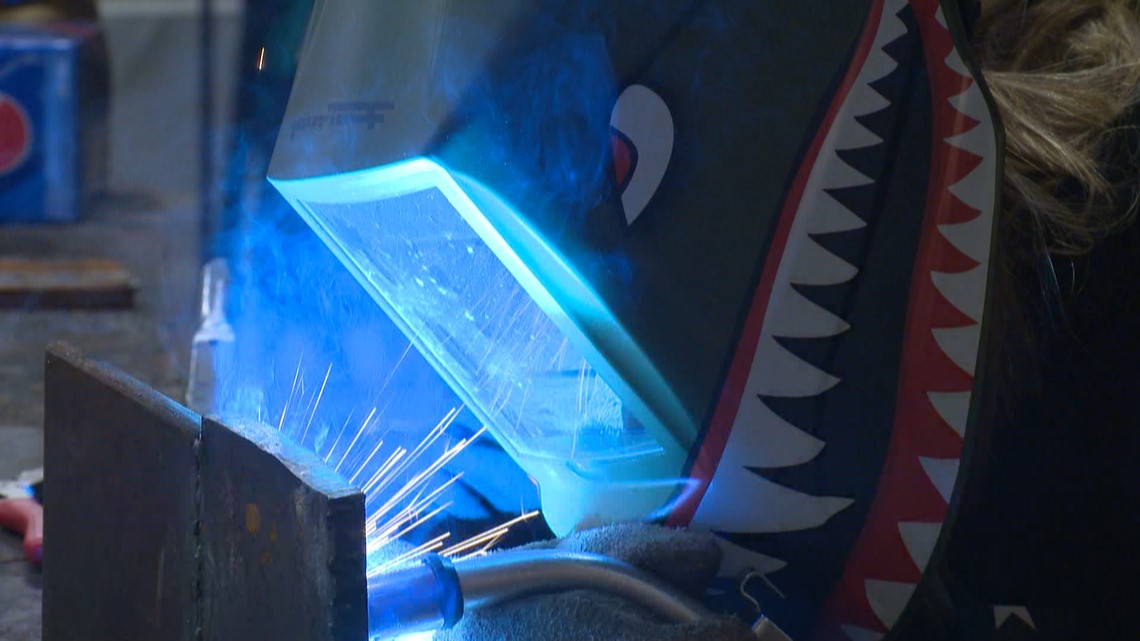

EAGLE CREEK, Ore. — Inside David Richards' personal shop at his Eagle Creek home, sophomore Dakota Dehaven, one of Richards' students, fires up a torch and begins welding the sides of a sheet metal dice cube together. Dehaven has been working on the cube for the last couple of months. On Tuesday, he's nearing its completion.

Dehaven said he got into welding because it sounded fun.

"I like welding and stuff and then they closed the program at the school and [Richards] offered to have us come here and do it here," Dehaven said.

In June, Richards was let go from his teaching job at Estacada High School, a position he had held for the past two years.

"I mothballed all the machines, I oiled all the machinery, I topped off all the cylinders, I cleaned out the shop," Richards said. "If and when they decide to reopen it, they're going to go back to a fully-stocked, ready to walk in the door, turn the key and turn on the lights. They've got a welding shop running."

Before teaching at Estacada, he was the metal shop teacher at Fort Vancouver High School for 15 years.

"We yanked the rug out from a whole bunch of kids in Estacada when the superintendent made the decision to close down the welding program." Richards said.

Estacada School District was facing a 5% budget cut due the effects of the COVID-19 pandemic. A spokesperson for the Estacada School District said the metal shop's class was cut because it and Career Technical Education classes had received the least amount of support.

"The trades are screaming, crying, kicking, they need what we were producing at Estcada High School's metals program," Richards said.

In November, he opened up his personal shop and began a welding class of his own. For $25 a class, three to four students work on their welding skills each night. Each class session is a month long.

"Instead of having to work for a grade, I can work for what I want," senior Meadow Copher said.

Besides loving to teach, Richards said, "I see it as a community service mission that somebody has got to bring the next generation along."

Copher said she was never a big fan of school until she discovered welding.

"I just had fun learning all the different types of welding and all the different angles," she said. "Just a challenge myself just to see if I could do better."

She, like many of the students, are working towards their AWS 3G welding certificate.

"It's pretty difficult," Copher said. "Just have patience. You have good days, you have bad days. Just got to keep doing it."

Richards isn't just teaching them how to weld, he's helping to set them up with a possible career path once they complete their certification. As a teacher he said his students were getting jobs out of high school.

"Every kid that was interested in doing what we were turning them out, had $18 an hour jobs to start," Richards said. "That's not minimum wage, that's to start. We were having kids hired at Warren Industries, we were going the apprenticeship route."

Richards said he doesn't do this for the money, he said it's more about passing on what he knows to the next generation and setting them up for success.

"Every generation owes it to the next generation to impart the knowledge that you have gained, so that they don't have to start over," Richards said.

If you'd like to learn more about David Richards' program, he said to email him at dric288@gmail.com.